VVVF speed has become a popular way that can be widely used in various industries.

In the variable frequency motor speed control system, using a power electronic inverter as a power supply, it is inevitable that there will be high harmonics, harmonic greater impact on the motor. Mainly reflected in the magnetic circuit and the circuit harmonic magnetic potential, harmonic currents. Different amplitudes and frequencies of harmonic currents and magnetic flux will cause the motor stator copper loss and rotor aluminum consumption. These losses of motor efficiency and power factor reduction, the majority of these losses are converted into heat, causing additional heating of the motor, causing the motor temperature to increase, resulting in a temperature generally 10-20%. As a result of electromagnetic interference, power, conduction, and radiation, the stator winding insulation ages, resulting in deterioration of the common-mode voltage and leakage current of the accelerated bearing, bearing perishable, while the motor is screaming. Since harmonic electromagnetic torque, constant harmonic electromagnetic torque, vibration harmonic MMFs, and rear rotor harmonic current synthesis. The torque of the motor will generate pulsating issues, so that the motor speed vibration is low.

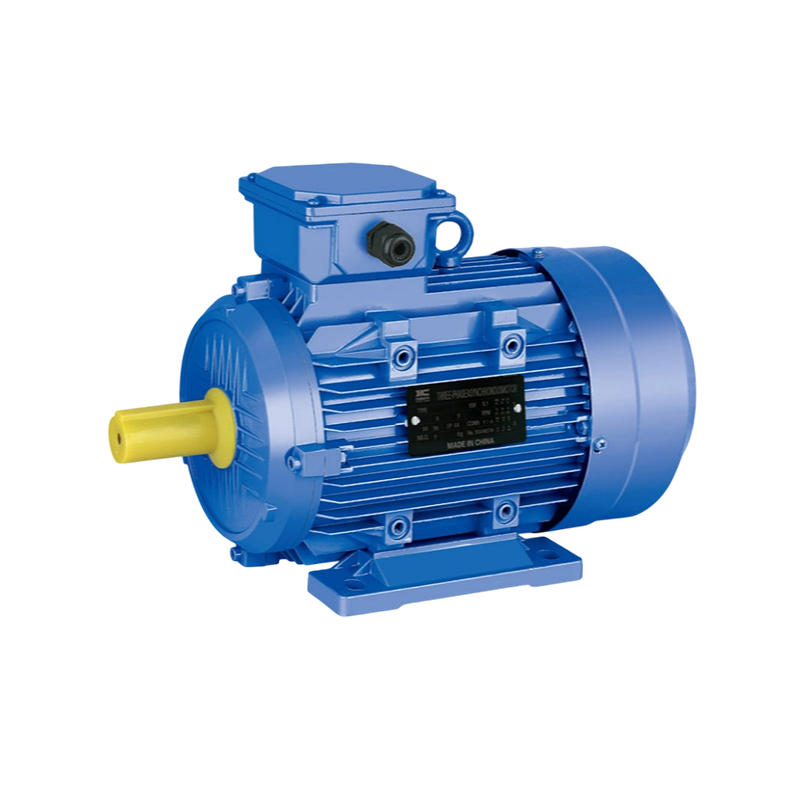

The company produces YS, IE2, and IE3 Series universal three-phase asynchronous motor design, our main consideration is the motor overload, starting performance, efficiency, and power factor. Another major consideration for non-sinusoidal motor power adaptability. Suppress the influence of higher harmonic current on the motor. Since the motor is increased when the working temperature of the low-frequency region, class F insulation class above, the use of polymer insulation materials and vacuum pressure impregnation process, and the use of special insulation structure. In order to reduce the electromagnetic torque ripple, improve the precision of mechanical parts to improve the quality level constant, and use a high-precision bearing mute. To eliminate vibration, the motor structure is strengthened to strengthen the overall design.

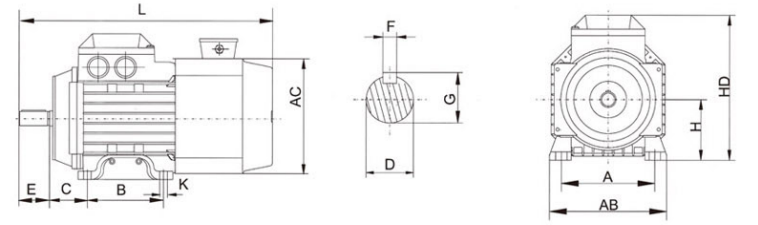

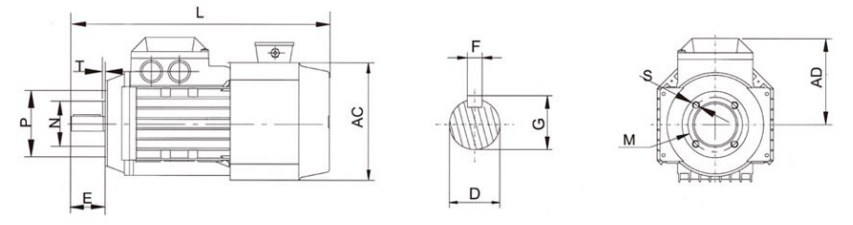

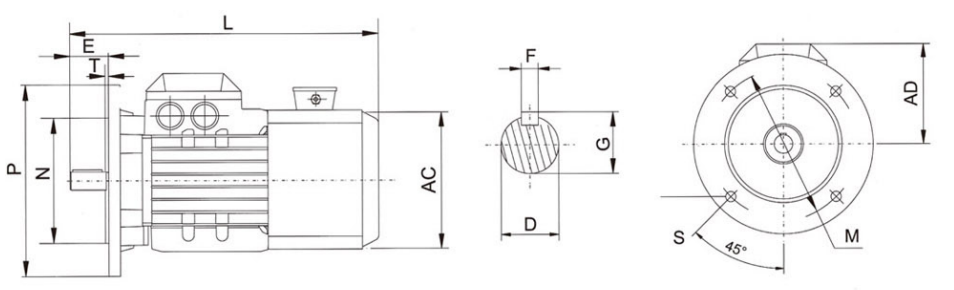

Since the motor is in a low frequency region, because the motor speed is reduced leaving the original ventilation system designed to reduce the role of the motor temperature rise, so the rear end of the motor with a single-phase 22ov or 38ov three-phase individual axial cooling fan, to protect effective cooling of the motor at any speed, the electric motor can run at hight speed or low. I produced YVF brakes that can be equipped with a three-phase inverter motor can also be equipped with an encoder to achieve low stepless speed control. With the IEC standard flange installation dimensions, the YVF three-phase inverter motor keeps good universal, and it can be interchanged with a general standard motor.

English

English