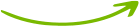

Brake motor is made of two parts consisting of three-phase asynchronous motors and brakes, it belongs to the three-phase asynchronous motor derived series. Manual brake release and bolt release are two forms of brakes. Brakes are the main components of the brake motor. Its working power divided into two categories; One is AC brake, the other is DC braking, my company produces brake motors are DC brake motors, the advantage of the braking torque is below, Easy installation, braking response speed, high reliability, versatility and other advantages.

1. Operating principle

After the motor is equipped with a cover, an asbestos friction disc, wear-resistant materials, and an excitation coil. When the motor is energized, a spring brake friction disc is pressed firmly against the plane by a pressing plate after the motor cover has been processed, so that the brake disc friction torque generated is strong achieve braking purposes. When the excitation coil is energized to produce electromagnetic suction, pull the spring-loadedplate, and the pressed board leaves the friction plate. The friction disc is released, the motor's flexible rotation, depending on the motor power, between tens and hundreds of revolutions per minute

resistance.

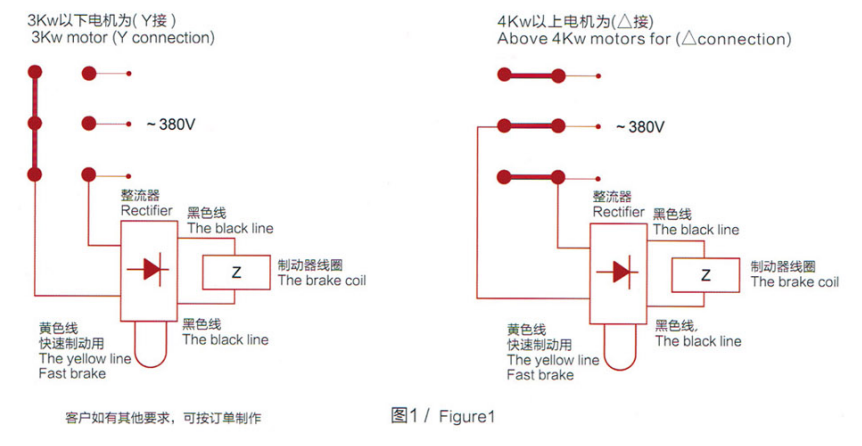

2. The DC brake can not be directly connected to the AC power; the brake coil is provided with suction cups for low-voltage winding rated DC voltage. A single-phase AC power is rectified and then supplied to a sucker winding to make it work, so the brake motor terminal box is fitted with a rectifier. The wiring diagram is below.

3. The braking time

Brake motor braking time (t) is the time from the motor and brake stopping the power to the shat completely stopped, under normal circumstances, For 63 to 80 frame size motor, the braking time is 0.5 seconds, For 90-132 frame size motor, the braking time is 1 second, For 160 to 180 frame size motor, the braking time is 2 seconds.

4. Adjustment and maintenance

In the course of braking, the motor increases the number of brake friction disc wear condition will exist, so the gap between the motor cover plate and the friction disc increases. Changes to the long-term operation of the motor, the motor directly affect the gap between the braking torques. When adjusting, the gap is not too small, the gap is too small, the friction disc friction with the motor cover can not be completely separated from the plane and burn the motor, the gap is too large, the pressed board can not pull or pull a strong noise process. Brake pressing plate at the gap, magnechuck brakes, generally for 60 to 112 frame size motor, the brake gap between 0.25mm to 0.30mm, for 132'180 frame size motor, the brake gap between 0.50mm to 0.80mm.

5.The inwerter nuns te molor brakc

With the continuous improvement and development of the social productivity of science and technology. The brake plus inverter system has been widely applied in the implementation of the organization. I produced all asynchronous motors that can configure the drive to run. At this point, the brake must be provided separately stable power supply must be provided, and then it can not be shared with the power terminals on the motor. Otherwise, the brakes do not work properly. Need to make is brake motors with variable frequency operation, an axial flow fan to attach this fan only independent control and power.

Notably, the company produces all kinds of asynchronous motors in the highest frequency range 6oHz, as you have special requirements, please let us know.

English

English